PBN has an ecosystem-oriented approach to the implementation of knowledge transfer, realized in a broad European partnership.

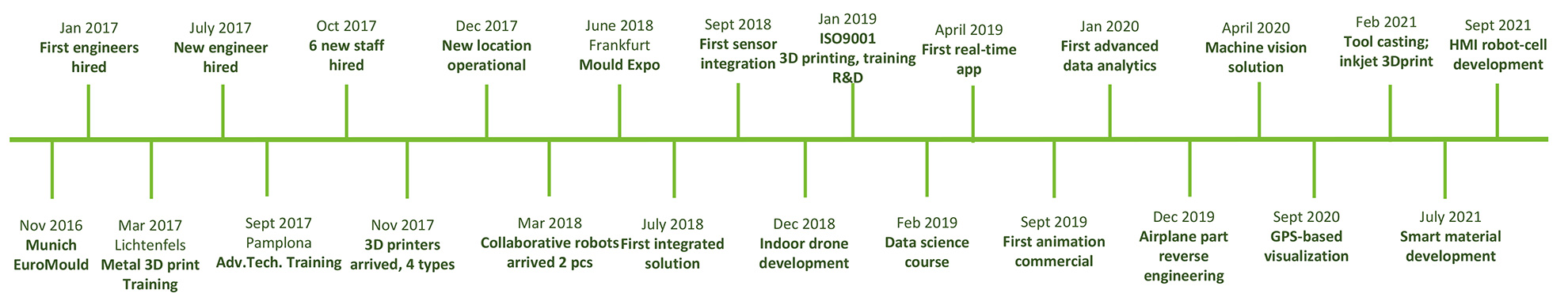

am-LAB is a research, development, and training laboratory focusing on application of digitalization in manufacturing and product development. It provides a holistic physical environment to meet unique business needs with cutting-edge technology.

at.home is a unique demonstration and test environment, a research & development infrastructure that facilitates the implementation of product and service development in the field of senior care.

With a wide range of equipment and an expert engineering team, am-LAB provides a competitive research and development environment, primarily for manufacturing companies. The Innovation Center also actively supports the successful implementation of at.home's health developments and PBN's international partnership and research projects. Founded in 2017, am-LAB won the title of Best Digital Innovation Center in Europe in 2020, in recognition of EU Commissioner Thierry Breton.

During the training consisting of interactive modules, the technologies and smart devices related to industry 4.0, their applicability in production processes, their impact on productivity and their application possibilities tailored to the company will be presented.

Our trainings cover the following topics:

Students and teachers of educational institutions are welcome to expand their experience free of charge. We provide an opportunity to try out the tools and technologies related to the thematic areas during the visit.

Covered topics:

Teaching and learning factory unit

Teaching and learning factory unit  Product development,prototyping

Product development,prototyping 3D printing

3D printing 3D modelling

3D modelling 3D scanning

3D scanning Collaborative and autonomous robotics solutions

Collaborative and autonomous robotics solutions Augmented reality technologies

Augmented reality technologies Data analytics

Data analytics

managing director

project coordinator

R&D engineer

R&D engineer

R&D engineer

R&D engineer

quality assurance manager

R&D engineer

R&D engineer

R&D engineer

R&D engineer

dual student - program designer IT specialist

For a personalised offer please contact our colleague below:

Joós Attila

Division Leader

attila.joos@pbn.hu

+36 30 330 2112

Central contact details:

+36 30 217 7934

info@am-lab.hu