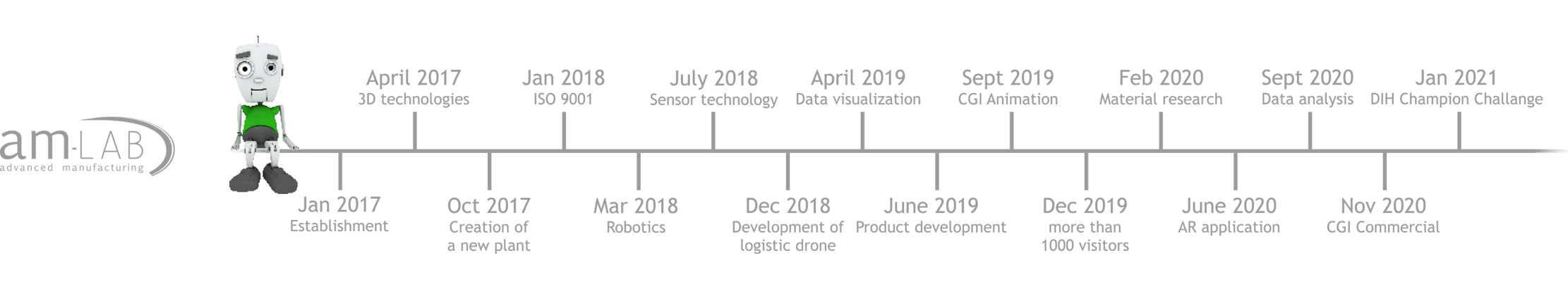

am-LAB aims at holistic digitalization support, with a broad service portfolio. It ranges from additive prototyping and series production, custom-based computer animation (CGI), augmented reality (AR) applications, through prototype development support, to data analytics, involving artificial intelligence-based algorithms.

am-LAB was awarded the honouring best digital innovation hub title of 2020 at the 1st European Digital Innovation Hub Conference.

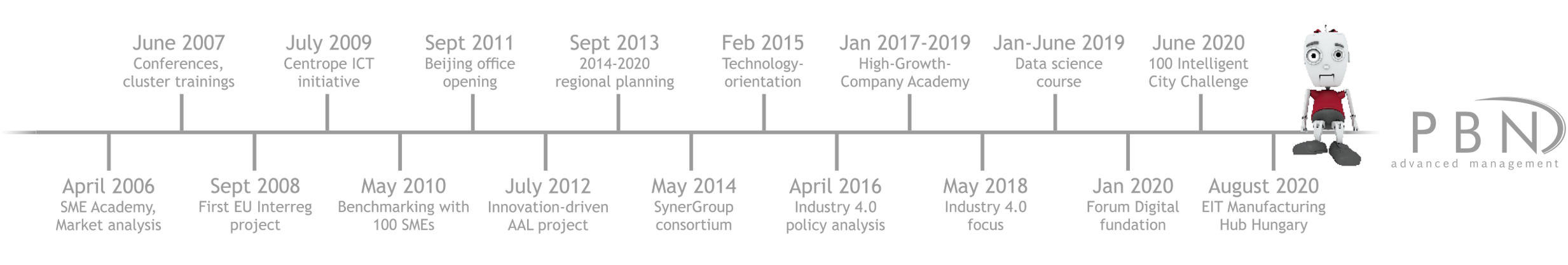

PBN is the mother company of am-LAB, focusing on applied research-development and training. Its unique proposition is built on the combination of business and technical competencies, a leading role in the adaptation of latest technological novelties, and its alone-standing international relations in Europe.

PBN has working experience with over 450 international partners in more than 75 research and development projects. Unique reference is the management of a Hungarian national business development academy reaching over 2,000 companies.

Development of extended reality applications for iOS and Android devices in the following areas:

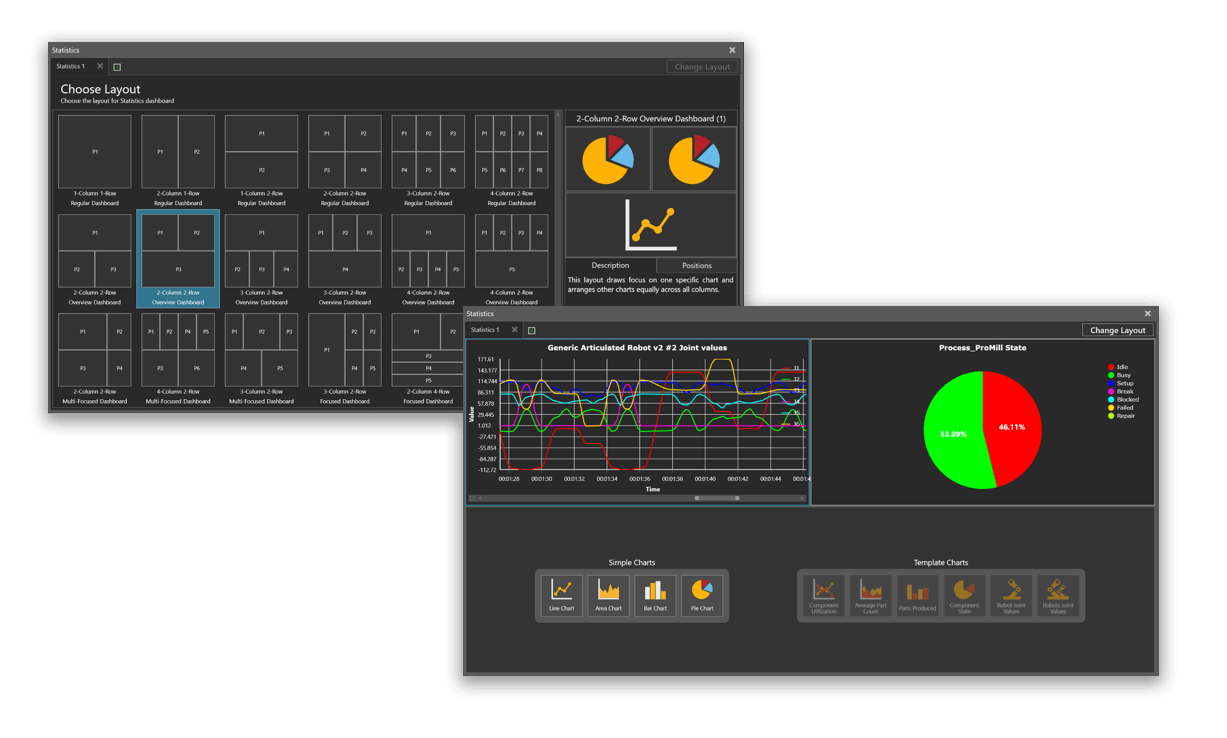

Increasing the profitability and efficiency of businesses by analysing previously untapped but valuable data. Our service enables smaller businesses to profit from data analytical services.

Our main focuses:

Development of a multiple robot solutions for various workflows and functionalities at manufacturing companies

Interactive training modules include industry 4.0 related technologies and smart devices; the applicability of these devices in manufacturing processes, and their impact on productivity; the potentials within the integrated solutions and their company-specific application possibilities; by examining their impact on the management of the business within a modern lab with digital manufacturing tools.

We are proud to say that so far more than 700 students visited our laboratory.

We welcome students and their teachers from educational institutions for a free experience-based knowledge expansion.

Topics covered during the career-orientation:

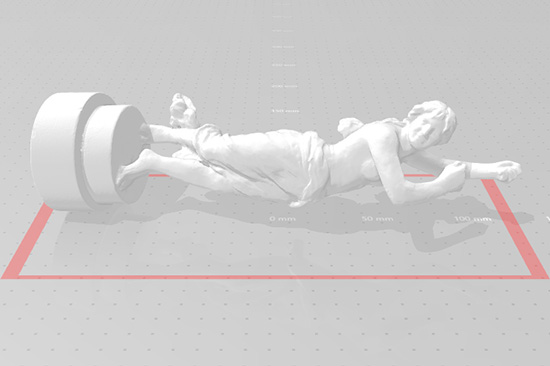

Prototyping

Prototyping 3D modelling

3D modelling 3D scanning

3D scanning Extended reality

Extended reality Collaborative and autonomous robotics

Collaborative and autonomous robotics Sensor-based data collection and analysation

Sensor-based data collection and analysation During the study visit we provide an opportunity to try out the presented tools and technologies.

During the 1-1.5-hour presentation, we can receive a total of 20 people at a time.

am-LAB is a demo and research factory facility, interested partners are welcome, based on preliminary conciliation and appointment.

Managing Director

Project Coordinator

Production and

Innovation manager

Production and

Innovation manager

Electric engineer and

Innovation manager

Robotics Technician

Robotics Technician

Quality Manager

Project Manager

Electric engineer and

Innovation manager

Materials science expert

Dual computer science engineer student

Innovation manager

For a personalised offer please contact our colleague below:

Joós Attila

Division Leader

attila.joos@pbn.hu

+36 30 330 2112

Central contact details:

+36 30 217 7934

info@am-lab.hu